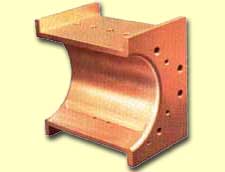

Tiger Bronze provides a smooth bearing surface that insures longer service. This means less shaft and bearing wear than is the case with harder alloys. It also means that Tiger Bronze will conform more readily to the tiny irregularities of the shaft and help to improve the distribution of the film of lubrication, both of which are very important during the critical "run-in" period. Tiger Bronze also prevents shaft seizures during periods of metal-to-metal contact caused by lubrication failures

Shock-Resistant and Embedable

Tiger Bronze is sufficiently hard to carry heavy bearing loads without distortion. At the same time it will embed foreign partiles that might otherwise score the shaft. Its physical properties, which are shown below, enable it to withstand severe shocks, pounding, and heavy loads, both constant and intermittent.