Look At the Capability That Backs Up Every Lubrite Product

Design Engineering / Testing Laboratory / Bearing Materials / Lubricants /

Bearing Assemblies / Machining / Welding / Quality / Service

A bearing is only as good as the engineering and manufacturing skills that go into it. Capability is evidenced by the long and successful experience of our engineering staff. The group has at its disposal a comprehensive data-bank on bearing design and performance. This knowledge is the result of experience in a wide variety of applications, and is now supplemented by our computer-assisted design and engineering program. In addition, engineers always stand ready to provide you with the full benefit of this experience -- from preliminary design assistance through field engineering. More than 80 years of research, engineering and manufacturing know-how stand behind every Lubrite® bearing.

Back to top

Testing

Laboratory

Lubrite® Technologies maintains a sophisticated

in-house testing laboratory for research and development as well as production

testing. If required, new designs can be tested under simulated field

operating conditions to ensure successful performance. Precise parameters

such as load, speed, and environmental conditions can be duplicated.

Back

to top

Bearing

Materials

A Lubrite® bearing system consists of

two basic components -- the bearing substrate and lubricant. This makes

detailed knowledge on the application of bearing materials extremely important.

The substrate

materials selected for a bearing system can vary considerably based on

the application. Bronze is commonly used, but in unusual environments

other materials ranging from stainless steel and nodular-iron to tool-steel

can be employed. Metallurgical experience assures you of proper selection

and maximum bearing life.

Back

to top

Lubricants

Lubricants used in Lubrite® Technologies'

products are compounds or composites dry, solid, permanent, and completely

self-lubricating. They do not require any form of supplementary lubrication.

Decades of research and development have been put into developing lubricants

and they are constantly tested both in our laboratories and in the field

to ensure performance, and to develop further improvements.

A number of

lubricants have been developed to meet the specific needs of a wide variety

of applications. One of these lubricants will provide the operating characteristics

needed for your application.

Back

to top

Bearing

Assemblies

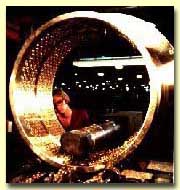

Lubrite® Technologies has the in-plant

capability to manufacture extremely large self-lubricating bearings and

accompanying assemblies -- such as the 30,000 lb. bearings used in the

Thames Flood Defense Project in London, England. Lubrite® Technologies

generally supplies all the peripheral parts needed to complete a bearing

assembly, including support systems, structural components, mating pins,

housings, and any other special requirements. The combination of our metallurgical

experiences with an in-house foundry and state-of-the-art welding capability

facilitates manufacturing even the largest assembly parts. Assemblies

as large as 35 tons have been built in our plant. It is recommended that

complete bearing assemblies (including pins, shafts, and all related steel

components) be designed and manufactured by Lubrite® Technologies.

This approach assures perfect mating fits of system components, a fast,

efficient installation, and superior bearing performance.

Back

to top

World's largest spherical, self-aligning bearing. This bearing has been in continuous operation in a harsh environment since 1976, protecting London from tidal flooding.

Machining

Lubrite® Technologies' modern machine

shop with CAD/CAM and CNC capabilities performs all of the machining operations

required in manufacturing Lubrite® products, assuring consistent quality

and on-time deliveries.

Back

to top

Welding

Superior welding skills are required to produce

mating surfaces of unusual metals. One example is the use of Submerged

Arc welding techniques by Lubrite® welders to overlay surfaces with

materials such as Inconel 625, Monel, and stainless steel. Lubrite®

welders are qualified to meet the requirements of the AWS structural welding

code and AASHTO.

Back

to top

Quality

Assurance and Control

The first and most important step in quality

control is quality assurance. Once product specifications are established,

Quality Assurance develops step-by-step manufacturing guidelines to ensure

the finished product will meet your requirements. Each stage in the production

process is then monitored by Quality Control personnel to be certain of

adherence to the guidelines. A reporting system that documents every interval

of the manufacturing process and provides complete traceability is an

important part of the program. Non-destructive testing is done by

personnel qualified to ASNT, SNT - TC - 1A. All destructive testing meets

specifications of ASTM. Every inspection is documented for your reference.

Back

to top

Lubrite's

Service

Lubrite® Technologies' philosophy is

one of involvement and committment. Our personnel are always available

to work closely with your own staff. Your customer service contact at

Lubrite® Technologies will help you establish the original design

concept, and then follow through to delivery of the bearing to your site.

Arranging field inspections, handling expediting requests, providing test

and certification documentation, and supplying any other information you

may need are all part of your customer service representative's role in

assuring you of superior service. If you have a special requirement, such

as field engineering assistance after installation, this can also be easily

arranged.

Before, during,

and after startup of your project, you always have the assurance of knowing

Lubrite® Technologies' complete capability is as close as the nearest

telephone.

Back

to top